Common advantages of silicone sealing strips

2023/06/15

Commonly used materials for sealing strips are silica gel and EPDM rubber. Generally, silicone sealing strips are often used in waterproof sealing. So besides waterproof sealing, what are the advantages of silicone sealing strips? Next, I will take you to understand the common advantages of silicone sealing strips.

1. Easy construction and installation, easy operation.

2. It has good heat resistance and cold resistance, and can be used for a long time in the environment of -50~250 ° C. It is a kind of common rubber with more important cold and heat resistance.

3. Good waterproof performance.

4. Silicone sealing strip has good compression deformation properties, such as: thermal expansion and contraction, instantaneous load, temperature difference deformation, snow load, etc. The good compression deformation of silicone sealing strip for construction makes it achieve a good sealing effect.

5. Small specific gravity and good elasticity.

6. Good physiological inertia and tasteless.

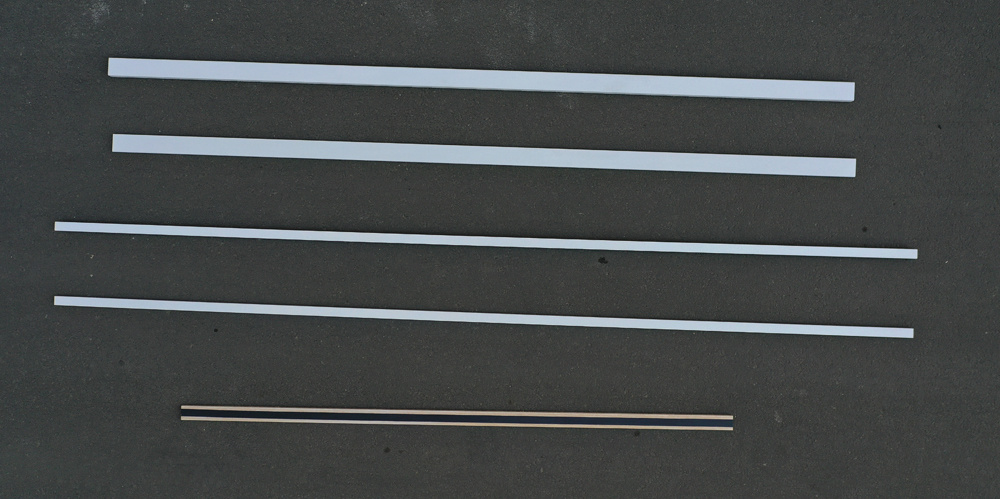

7. Most of the general rubber sealing strips can only be made in black, but the silicone sealing strips can be matched with various colors according to the needs, and the color performance is good.

Silicone seals can sometimes be marked by external printing, but due to their low surface energy, the ink does not adhere very well and can be easily wiped off during cleaning with common solvents. Silicon can also be used for color mixing, and barium sulfate is often used as a white filler for base color mixing, or for coextruded strips of X-ray opaque devices.

Key words:

sealing strip

Related Products